3 Step Order Processing

Looking for custom packaging? Make it a breeze by following our four easy steps - soon you’ll be on your way to meeting all your packaging needs!

Send Quote Request

Just fill up the quote form and submit it for evaluation by one of our packaging experts.

Consult with our expert

Get professional advice on your quote to cut costs & improve efficiency.

Production & shipping

Allow us to handle the full manufacturing and shipment once everything is prepared for production!

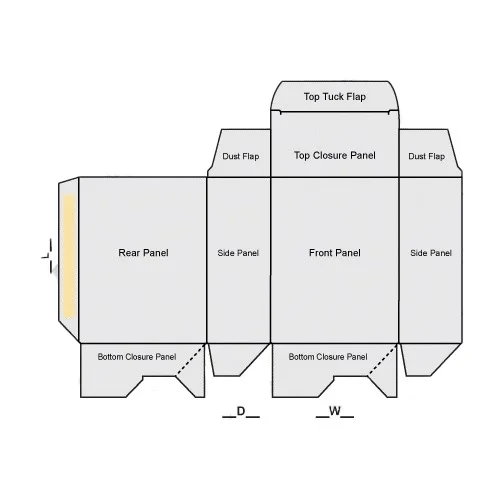

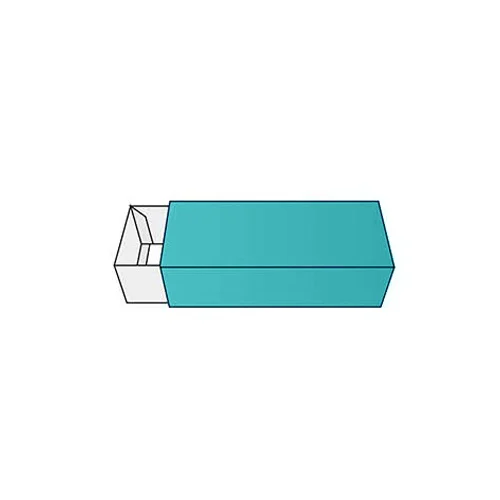

A Tuck End Auto Bottom (TEAB) refers to a type of packaging used primarily for folding cartons. It describes how the box's top flaps fold down automatically when the bottom flaps are pushed upwards. It creates a clean and finished look without requiring additional tape or glue. This packaging style is commonly seen in industries where food, electronics, and pharmaceuticals need to be stacked or stored efficiently.

Comparison between Tuck End Auto Bottom and Other Closure Methods such as Stapling and Hot Melting

Tuck End Auto Bottom boxes offer distinct advantages over other closure methods like stapling and hot melting. TEAB boxes feature tuck-in flaps on both ends, ensuring secure closure without the need for additional materials. They save time during assembly with their automatic bottom, making them efficient and user-friendly. In contrast, stapling requires additional tools and can pose a risk of damaging the product. Hot melting, while providing strong seals, demands specialized equipment and can be messy.

TEAB boxes allow for custom printing, enhancing branding opportunities and marketing impact. Stapling and hot melting may limit customization.

Moreover, TEAB boxes are eco-friendly when made from recyclable materials, promoting sustainability. In general, TEAB boxes strike a balance between convenience, security, and branding, making them a top choice for versatile and efficient packaging solutions.

Future Trends and Developments in TEAB Technology

In the future, Tuck End Auto Bottom technology is set to undergo significant advancements. Smart packaging integration with Radio Frequency Identification (RFID) and Near Field Communication (NFC) technology will enable product tracking and consumer engagement.

The industry will shift towards sustainable materials, promoting eco-friendliness and reducing the carbon footprint of TEAB boxes.

Enhanced security features like tamper-evident measures will ensure product authenticity and consumer safety.

Custom printing will become more accessible, allowing on-demand production and personalized packaging.

Innovative opening mechanisms, interactive elements like AR, and QR codes will enhance the unboxing experience for customers.

TEAB boxes will feature simplified recycling designs, encouraging sustainable waste management practices.

The future of TEAB technology promises greater functionality, sustainability, and consumer interaction, revolutionizing packaging methods.

For more information about upcoming TEAB technology trends, reach out to the packaging specialists at The Legacy Printing.

| DIMENSIONS |

All Custom Sizes & Shapes |

| PRINTING |

CMYK, PMS, No Printing |

| PAPER STOCK |

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| QUANTITIES |

100 – 500,000 |

| COATING |

Gloss, Matte, Spot UV |

| DEFAULT PROCESS |

Die Cutting, Gluing, Scoring, Perforation |

| OPTIONS |

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| PROOF |

Flat View, 3D Mock-up, Free Sample Kit (On request) |

| TURN AROUND TIME |

8-10 Business Days , Rush |